The most common method of electrically connecting and supporting electronic components is by using conductive tracks, pathways, or signal traces. They are made up of layers of insulation with one or more copper conductor patterns. They are also known by the name printed wiring boards, or PWBs. They can be found in nearly all commercial electronic devices.

There are two common alternatives to PCB: point-to-point and wire wrap. This printed circuit board should be well designed and laid out. They are therefore expensive to make individually. They can be made in large quantities and are therefore much cheaper and easier to produce. The IPC organization determines the design and quality requirements for PCBs used within the electronics industry.

There are many factors that need to be taken into account when designing printed circuit boards. It is important for beginners to learn how to optimize their designs taking into consideration the cost factors. Many new designers fail to grasp the importance of spacing and basic width. These factors have a significant impact on the manufacturing cost and the unit price.

Following are three main things you must consider when manufacturing PCBs if you are new to PCB industry. Some few points are Board Shape, Board Sizes and Hole Sizes etc.

There are mainly three types of circuit boards that are being used widely which are as follow:

- Single Sided PCB

- Double Sided PCB and

- Multi-layered PCB

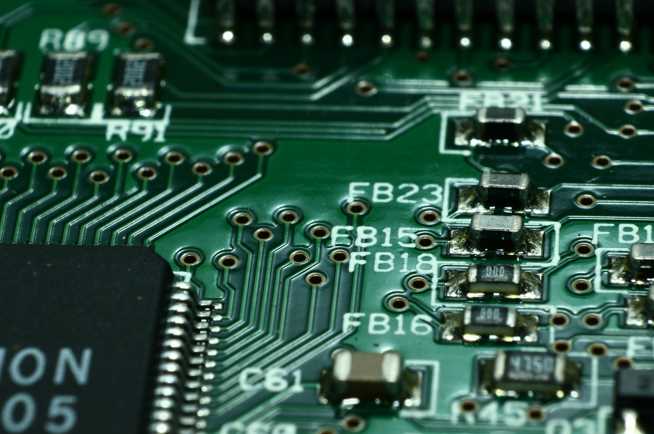

Because of misinformation, many people aren’t comfortable working with surface mount technology (S.M.T.). Although there are many good resources for commercial assembly, not much information is available about prototyping or hand soldering using S.M.T.

S.M.T. is an electronic component package. The Surface Mount (S.M.) is one type of electronic component. The second category is the through-hole (T.H.). S.M. components can be used for soldering and loading on a particular side of the printed circuit boards. T.H. is for printing and loading on one side.

Why do S.M.T.s are used in industry?

S.M.T. has many advantages over T.H. They are smaller in size and have the same electrical function but are less expensive. S.M.T. has the greatest advantage: no drilling is required through the board. This allows for more trace, and therefore a smaller board.

Why do you need to care about Surface Mount Technology?

S.M.T. is a growing problem for those involved in the development, repair and modification of electronic devices. As producers increase their investments in S.M.T. production equipment, S.M.T. equivalents quickly replace the T.H. parts.

S.M.T. Myths

These myths include the belief that S.M.T. requires special training and expensive equipment. S.M.T. is not a problem for most printed circuit board assembly companies. Before you place an order, find out.

Tip: Use S.M.T. without Stress

You can use S.M.T. with no stress if you practice your technique and have good eyesight.

What can S.M.T. do for you?

- M.T. has many advantages over the traditional leaded components. These benefits include:

- M.T. resistors can be easily connected in parallel and are quick to solder or de-solder. It is easier to work on one side of the board simultaneously, which reduces frustration.

- Unwanted effects in S.M.T. parts can be less than parts when using R.F. signals

- M.T. parts can fit in the spaces of VERO boards and can be mixed with designs that use leaded parts.

- M.T. simplifies hole drilling by allowing you to load and solder simultaneously.

Tips for soldering S.M.T. Parts

Practice is key to mastering soldering skills. A few tips are helpful, such as keeping the circuit board clean and selecting the right tip. Also, you can use solder flux whenever possible. S.M.T. resistors are great for practicing because they are resistant to damage.

What parts are recyclable?

Many S.M.T. parts can be obtained from scrap or used equipment. This saves money and allows for good de-soldering. Ceramic capacitors crack easily and are problematic. While it is possible to verify the operation of resistors, inductors, and transistors, excessive heat can cause damage. There are a few good suppliers of components that can provide a complete list of all parts. Victory PCB is one of these more well-known suppliers. You can also salvage old computers, mobile phones, televisions, and other devices.