The hydraulic breaker hammer is a construction machine that breaks rocks and concrete into manageable pieces. It uses powerful, hydraulics-driven hammers to do so. The engineering article below classifies how these machines work:

1) What’s the principle behind them?

2), How does it function on an excavator or backhoe for example

3). Or what about when we’re talking mini-excavators versus stationary plants?”

This section of the book provides a great deal of technical information. If you have experience in engineering, this will help explain how hydraulic hammers work and operate on an operational level by using flow charts that are not too tedious or tough to understand.

This is a technical description of how hydraulic rock breaker hammers work. It’s perfect for someone who has an engineering background, but it might get tedious if you don’t understand all the terminology or flow charts that are used throughout this section. There are four images and one video to help clarify what people see when they look at our operating principle.

What are the General Characteristics of a Hydraulic Breaker?

In preparation for construction activities, there are several phases of work. First and foremost is demolition which includes removing obstacles in the way such as buildings or other structures that could be an obstruction if they were not removed beforehand so it’s important to have professionals who know what they’re doing take care this part because things can get pretty dangerous without proper precautions taken! Next comes site prep- ground breaking before any building begins on top with all sorts of difficult tasks like road surface excavation where you might need heavy equipment but luckily these days we’ve got compressed air hammers which do just fine at meeting growing economic demands while also being technically advanced enough.

The development team has been hard at work on a range of working tools for hydraulic excavators, which will be more specialized than traditional machine-tools and require less physical effort from the workers.

Innovation was triggered by a combination of factors:

· The hydraulic excavator becoming the main tool and being present on most construction sites,

· The universal applicability of the hydraulic drive system,

· The rapid replacement of implements,

· The need to reduce manual work,

· General requirements to increase machine utilization,

· Energy-saving and environmental requirements.

Some of the assemblies developed are suitable to replace specialized machines, while other decrease manual labor or increase productivity. The most common type may be pile driving equipment that allows for quick and efficient excavation work with none of the need for operators input required!

What are the advantages of a Hydraulic Breaker over Pneumatic Hammers?

· Increased utilization of excavators used as master machines.

· Decreasing human workforce, increasing performance.

· Compressor elimination.

· Its work output is many times that of a pneumatic one.

· No need for long air supply hoses.

· Better use: the hydraulic excavator.

· Fuel consumption is more favorable than that of a compressor.

· Moving compressors no longer causes a waste of time.

· With up to 30-40 times higher impact force, less noise, and risk of accidents.

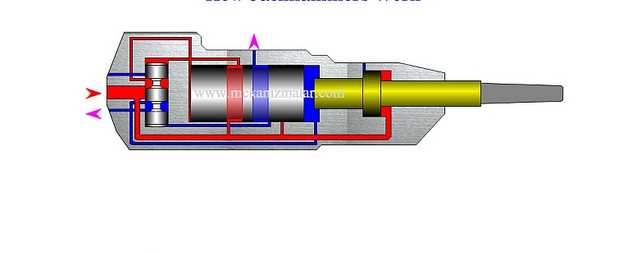

There are three main types of hammer. The beater, which rotates when impacted by an object being struck and is raised to the home position with oil supplied from hydraulic system on base machine. In some cases it can also have mechanical transmission or spring unit for downward acceleration during impact phase; pneumatic springs that provide natural force through air pressure in addition to gravity acting downhill via mass applied at top end causing upward accelerative force resulting into more efficient power transfer without making any contact between striking face (where most material damage occurs) and work piece surface while using less energy due mainly.

The hammer’s hydraulic system makes sure that it can perform its function under any conditions. The accumulator, which is what keeps everything running smoothly, ensures the right amount of pressure in order for things like movement or an explosion to happen as expected – without being too much or not enough at all times.

How Does a Hydraulic Breaker Work?

When the tool transitions from a lower to higher pressure, it moves upward and closes an outlet gap. The high-pressure oil acting on its working surface raises the striking piston until its bottom is at dead center (bottom of stroke).

The typical construction for this action includes putting together three main parts:

1) A cylinder with holes through which fluids will pass;

2) An arrangement that allows movement up or down under manual force;

3 )A device connecting these two components together so they can work as one unit when needed.

The high-pressure oil in the piston head compresses the energy storage (nitrogen gas) until finally, when released through an exhaust valve by way of combustion taking place at just over 2000 degrees Fahrenheit – this force propels it downward with great unrelenting power.

Closing Thoughts

This article has helped you understand what a hydraulic breaker is, how it works and the types of applications available. We hope this information helps you better utilize your new found knowledge in any future projects or endeavors. If you have questions about our services please contact us for more information.

Hydraulic breaker is a machine that uses the force of high-pressure water to break up tough materials like asphalt or concrete. It can be used for demolition, construction, and more. Hydraulic breakers are not limited in their use but they do have some limitations when it comes to size and power. Using hydraulic breakers requires skill so if you’re looking to hire someone with experience operating them, give us a call! We know all about how these machines work because we install hydraulics too.