Mechanical parts fill complex machinery, and we need them to perform specific tasks. Taking raw material and forming it into a part for this machinery requires precision machining, which involves using various machining operations and processes that are difficult to perform by hand or with simple tools.

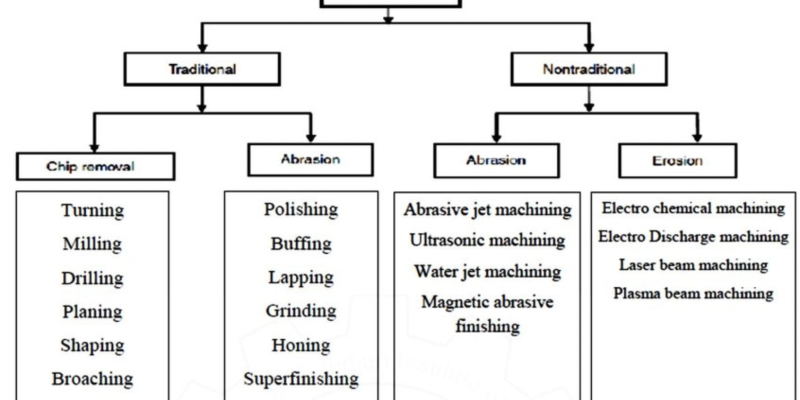

There are many different types of machining operations and processes. The most common ones are turning, drilling, grinding, and milling. However, there are also other less common machining operations and processes such as grinding, planing, and broaching. Each type of machining operation and process has its own unique set of characteristics and capabilities.

Let’s look into some of the different types of machining operations and how they work.

Milling – Manual Machining Operations

There are various kinds of milling operations and processes used in different industries. Milling is a machining process in which a cutter removes material from a workpiece.

The cutter is fed into the workpiece at a variable cutting speed and depth of cut. The speed and depth of cut are determined by the cutting conditions, including the cutter material, workpiece material, and cutting fluid.

The different milling operations and processes include face milling, end milling, peripheral milling, slot milling, plunge milling, contour milling, and die sinking.

Drilling Operations

Drilling is a cutting process that uses a rotary cutting tool to create holes in a workpiece. The drilling tool is typically a drill bit rotated by a Drill press or a hand-held power drill. The holes created by drilling are generally round, and the drill bit’s size determines the holes’ diameter.

Turning – Manual Machining Operations

Turning is a process where a workpiece rotates on a lathe, and material is removed from the workpiece using a cutting tool. This process is typically used to create cylindrical shapes or produce threads on a workpiece. Turning can be performed on various materials, including metals, plastics, and composites.

Turning is a machining process in which a cutting tool removes material from a rotating workpiece. For all of these processes, you need the best tools. Look to a professional provider like productionserviceco.com.

Grinding Operations

One of the most common types of machining operation and process is grinding. This uses abrasive particles to remove material from a workpiece. The particles may be in the form of a wheel, belt, or other abrasive devices.

The workpiece is usually rotated against the abrasive device to remove material. Grinding can remove heavy material, such as metal, from a workpiece. It can also remove smaller amounts of material, such as paint or rust.

Machining Operations and Processes Make Life and Work Easier

There are many different machining operations and processes, each of which has its own advantages and disadvantages. The machining operation or process most suitable for a given application will depend on several factors, including the material to be machined, the required tolerance, the desired surface finish, and the production volume.

For more information on machine operations and how they can make life easier, check out the rest of our blog.